Except as noted, all information in this article comes from the Final Report of the Board of Inquiry, of October 12, 1983.

Air Canada Boeing 767-200

On July 23, 1983, one of the most remarkable events in the history of aviation occurred involving Air Canada Flight 143. Flying a Boeing 767-233, Captain Robert Pearson and First Officer Maurice Quintal ran out of fuel mid-flight, at an altitude of 41,000 feet. These expert aviators landed the 80+ ton plane without seriously injuring or killing a soul, despite having to do so with no engine power and limited flight control power. Here is their story.

Flight 143, scheduled for a trip from Montreal to Edmonton, Canada, carried 61 passengers, 6 crew, and the two pilots. At the time, the 767 was a new aircraft only recently added to Air Canada’s fleet. It introduced a major upgrade to aviation at the time; it elided the need for a flight engineer in the cockpit, as the 767 used many new technologies that reduced the workload for the flight crew. For this trip, Captain Pearson operated the flight, and First Officer Quintal served as the pilot monitoring. A series of errors came very close to ending the journey in disaster, saved only by the extraordinary airmanship of this crew.

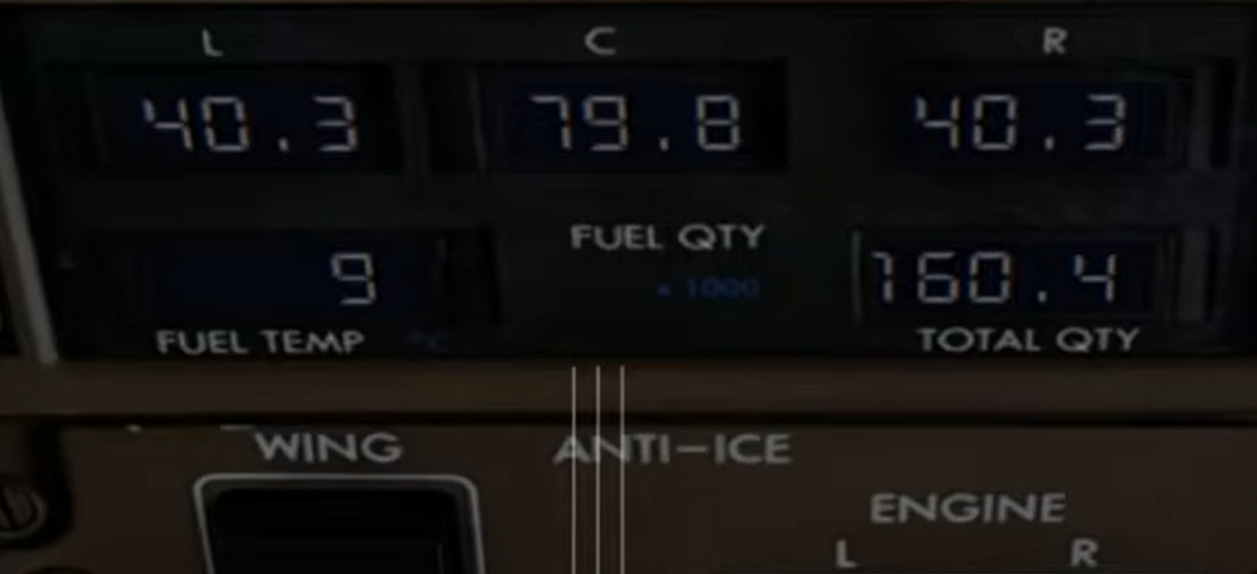

The first error occurred as a result of a technical problem. Digital fuel gauges, one for each tank situated on each wing and one for the tank positioned in the body, all were blank when aircraft technician Conrad Yaremko inspected them prior to the flight. The gauges were powered by two separate channels, so if one channel failed the other took over. Yaremko could not fix the misfunctioning channel, so he marked it inoperative and pulled the circuit breaker for it. Pulling the failed circuit restored the digital fuel gauge display (now operating on the single functioning channel 1). He properly reported the malfunction, recorded it in the onboard log, ensured that the aircraft remained airworthy despite the deficiency, and cleared the aircraft to fly. The Minimum Equipment List (“MEL”) allowed the aircraft to operate on a single channel, so long as the fuel levels were manually confirmed prior to the flight. Unfortunately, another technician, Mr. Ouellet, later examined the fuel gauges again prior to the flight and mistook the pulled circuit for channel 2 as a mistake. Upon resetting the circuit, the gauges again went blank. Ouellet attempted to fix channel 2’s processor, but like Yaremko, he could not because the airport did not have the needed part. Upon becoming distracted by grounds crewmembers, he never re-disabled the circuit for channel 2, which left the overall fuel display blank once more. Error #1.

When Captain Pearson arrived on the flight deck, he found the blank gauges and Yaremko’s entry in the log. Prior to boarding, Pearson had spoken to the pilot that had brought the 767 to Montreal from another leg, who told him about the problematic fuel gauges. Pearson thus expected there to be a problem with them, and was therefore not surprised to find them wholly inoperative. He did not know that they could have been operative had the channel 2 circuit been disabled. Nevertheless, following protocol, he consulted the MEL. He found that the rules forbade flying without at least one working channel, but determined the flight remained safe to operate regardless, as long as he manually confirmed the fuel load prior to departure. Pearson later testified that a “higher authority” at the airline had cleared the flight on the condition someone manually confirmed the amount of fuel onboard, irrespective of the inoperative fuel gauges and the MEL guidance. Error #2.

What the 767 fuel display normally looks like.

Following that, the next error occurred as a result of tradition. By that, I mean that up until the introduction of the 767 to Air Canada’s fleet, grounds crews measured fuel for aircraft in liters. Pilots, however, needed to know the weight of the fuel not the volume for flight operations, so they routinely converted the liters to imperial pounds (probably because American-based airlines used pounds). When Air Canada ordered the new 767s from Boeing, airline management decided to switch to the metric system for measuring aircraft weight, to put the airline in accordance with government policy. Fuel gauges in the 767, contrary to older aircraft, now displayed fuel in kilograms, and pilots had to calculate takeoff weight in kilograms as well. Calculating takeoff weight is a critical function as it determines the speed and configuration needed for an aircraft to successfully lift off and climb out. To manually measure the fuel in the plane, grounds crews used “drip sticks,” which were calibrated in centimeters. In order to confirm the overall amount of fuel in the tanks, drip stick operators had to convert centimeters into liters, and liters into kilograms. Because crews had previously always measured fuel in pounds, both the flight crew and the ground crew calculated the overall amount of fuel from liters to pounds instead of to kilograms. So, while Flight 143 should have received roughly 23,000 Kg of fuel, the crew only requested 23,000 pounds. At the end of this confusion, Flight 143 left Montreal with around 10,400 Kg of fuel, only about half of the necessary amount. Error #3.

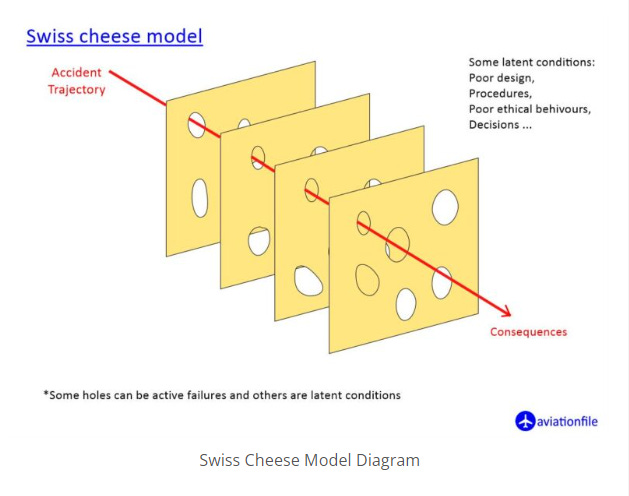

In aviation, virtually no accidents happen because of a single error. Instead, safety experts refer to the Swiss cheese model. Imagine stacking several pieces of Swiss cheese against each other. Single holes do not result in incidents. When the holes align, however, eventually an accident occurs.

This model focuses on finding the conditions (or “holes”) creating potential dangers, to allow for their correction. Because aviation accidents almost never happen from one error, post-accident investigations look for all the holes leading up to the incident to better inform policy and regulation to prevent future incidents. To date, this practice has made aviation the safest way to travel, mile-for-mile, of any form of transportation. Flight 143 did not benefit from this policy model due to the novelty of the problems leading up to the incident, but the application of the model afterwards led to several changes in procedures that enhanced the safety of future flights.

Problems on the flight began around 8pm Central Time at an altitude of 41,000 feet. A caution signal in the cockpit alerted the pilots to a problem with the left fuel pump. For reference, the 767 operates with two engines, and fuel pumps supply each with fuel from any of the three tanks (depending upon technical configurations). Captain Pearson believed that the caution signal indicated something wrong with the functionality of the indicated fuel pump. He even had Quintal double-check the fuel levels they should currently have onboard based on the distance they had traveled so far. Of course, Quintal’s calculations would be wrong because they were predicated on the incorrectly calculated levels with which they began the flight. And as the fuel gauge display was not working, they had no other reference. After a quick assessment, they immediately elected to divert to Winnipeg, 120 miles from their current location, and began descending. Seconds after making that decision, the right fuel pump warning alighted. In the few minutes it took for the aircraft to descend to 35,000 feet, the left engine failed followed almost immediately by the right. They were out of gas. At that point, the aircraft was still 65 miles from Winnipeg. The next closest airstrip was Gimli at 45 miles’ distance. Gimli refers to the Royal Canadian Air Force base located nearby the town of that name.

Without the two turbine engines, the 767’s electricity came primarily from backup batteries and the RAM air turbine (colloquially known as the “RAT”). Upon the initial flameout of the engines, the flight crew lost all of the electronic displays, including altitude, airspeed, descent rate, and operating parameters. While the backup batteries quickly restored some of the flight displays, the hydraulics needed to steer the plane’s flight surfaces did not receive sufficient power from the batteries. Deploying the RAT provided power—albeit significantly less than that produced by the engines—from the force of the passing wind. With this power, the pilots could control the flight surfaces to a limited degree. Not only did the giant aircraft no longer have forward thrust capability, the pilots faced gliding the behemoth to the ground with severely reduced flight controls. This meant steering—done through aileron and rudder movements—and pitch control—typically handled by the vertical stabilizer and trim—all required precision movements. Diminished controls left little room for error. Luckily for all aboard, Captain Pearson was an experienced glider pilot. Given his, and Captain Sully’s successful aversion of disaster on the Hudson River, one wonders whether all airline pilots should certify as gliders!

The RAT spinning below the fuselage. Source: http://ourame.blogspot.com/2010/12/air-driven-generatorram-air-turbine.html

Gliding an 80+ ton jet from 35,000 feet was no small task, even for an experienced glider. Captain Pearson would not get a second chance to line up with the runway, and he did not have the power or flight surface controls to make any significant adjustments. Moreover, unlike a normal landing, without power Pearson could not deploy flaps or slats to slow his descent or the rate of speed at which the plane would hit the pavement. Worse still, Boeing engineers believed the chances of a double-engine failure in the new 767 were so remote that they had not included an emergency procedure for pilots facing such a dilemma. This meant that Captain Pearson had to guess based on his own experience what speed to fly at and what angle to pitch the plane at to lengthen the glide as long as possible. In a plane without power, one must trade altitude (via pitch) for speed quite often. Finding the “sweet spot” requires extraordinary skill. Also because of a lack of power, the instrument indicating how fast the plane was descending did not work, even with the backup batteries. First Officer Quintal had to calculate their descent rate by taking readings from the altimeter and running them against distance traveled based on reports from Air Traffic Control. Upon performing several calculations, he realized they could not make it to Winnipeg; they decided to land at Gimli instead. Unfortunately for Flight 143’s pilots, the Gimli air base had closed quite some time before the flight and was since converted into a recreational place for private planes and for drag racing. Nonetheless, Pearson and Quintal didn’t know that yet and that issue took a back seat to more pressing problems anyway.

In a brief time, the crew had Gimli in sight. From their present distance, they could not see that many people sat around the airfield at the time, gathered for a “family fun day,” which included drag racing on the runway. Without the flaps, Pearson would have to land fast to prevent the plane from falling out of the sky. Landing at high speed risks both an overrun of the runway and severe structural damage to the body of the aircraft. To add a little more terror, First Officer Quintal could not make the landing gear deploy fully. Normally, the landing gear uses hydraulic pressure to drop into place and lock, but the RAT simply did not supply enough power to do so. Instead, Quintal relied on a “gravity drop,” using the weight of the gear to “drop” it into place and hope its downward force proved sufficient to lock it. Alas, it was not enough for all the gear. While the rear sets successfully locked into place, the nose gear did not drop at all. So, Pearson coped with a stiff-handling jet, with virtually no control over speed or rate of descent, lacking the gear under the nose, and loaded with 79 lives—including his own—all of whom depended on what he did in the next few minutes. No pressure.

As they approached the runway, both pilots noticed that the plane was too high. In their effort to maintain the glide, and without instruments to line up to the runway, they had not descended early enough for a smooth landing. This was a particularly vexing problem because as they neared the ground, the controls grew even more sluggish. Flight controls rely in part on the air passing over the flight surfaces of a moving plane. Slower passing air means less effective control capability. Pearson needed to slow the plane to land without breaking apart—it was already too fast as it was—but it severely affected his ability to maneuver in the absence of the usual flight control power. He clearly could not afford to miss the runway, but simply diving down toward it would increase his speed considerably, and raise the already significant risk level even higher of disintegrating on impact. Remember, they did not have the front landing gear either. Normally, if a plane comes in toward the runway too high or too fast, pilots deploy speed breaks. These are small flaps on the wings that disrupt the passage of air, which slows the overall speed but enables a swifter descent. Without engine power, however, the speed brakes were not available. Pearson faced a choice: find a way to get down quickly without adding forward speed, or risk missing the runway altogether and crashing into who knows where.

Falling back on his glider experience, Pearson opted to try something rather crazy for a 767 with so many flight control problems. He would attempt to pull a “forward slip” maneuver. This move, usually used by gliders and very small aircraft like Cessnas or Piper Cherokees, requires the pilot to lower the wing on the side toward where you wish to go, while at the same time applying the opposite rudder. The change in aerodynamics causes a rapid descent without picking up speed. It is something like drifting an 80-ton plane. Inside, passengers on one side of the plane would have seen nothing but the ground below them as the plane tilted sideways. Further complicating matters, with the aircraft now flying in an askew position, the RAT no longer received direct airflow, thereby reducing its power output and further eroding the flight controls.

Regardless, Pearson had to finish what he started. Just before the runway threshold, he yanked the plane back straight and essentially dropped its gigantic frame onto the ground, trying to heave most of the weight onto the rear landing gear. Pilots will often commit hard landings on the rear gear when the conditions are bad because the rear gear is made to withstand massive force, while the nose gear is not. A hard landing also consumes some of the momentum energy, quickly slowing the plane. For Flight 143, any force applied toward the front was going straight into the fuselage itself as it had no operating nose gear, so any reduction of speed at this point could only help.

Amazingly, Pearson managed to straighten the plane and let the nose sink. He applied the brakes hard and somehow centered the nose on a guardrail that had been built in the middle of the runway. This kept the 767 aligned to the middle of the strip, enabling it to stop before running off the end. From the friction of metal sliding on metal, the nose of the fuselage caught fire. When the plane finally screeched to a halt, crews on the ground who were prepared for possible dragster fires, raced to the downed Boeing, and extinguished the flames with handheld cannisters. In mere moments after stopping, every single person evacuated uninjured. Remarkably, no one on the ground suffered injuries other than the terror that must have hit them seeing the whole event unfold.

After all commercial aviation incidents new policies, procedures, and regulations are implemented to prevent this kind of event from occurring again. The Gimli crash resulted in significant changes in aviation in Canada. For their role in the fuel mishap that led to the incident in the first place, Air Canada demoted Pearson from Captain for six months. First Officer Maurice Quintal received a two-week suspension. Nevertheless, for their extraordinary airmanship in landing the crippled aircraft, both received the first-ever Fédération Aéronautique Internationale Diploma two years later, and both moved on to long, successful, respectable careers. The Gimli Glider, as the event and the plane is now known, is legendary in aviation circles. The aircraft was repaired and returned to service after the incident, and it held that name until its retirement in 2008. Pearson and Quintal had performed the longest successful glide of a commercial aircraft in history at that point.

***

I am a Certified Forensic Computer Examiner, Certified Crime Analyst, Certified Fraud Examiner, and Certified Financial Crimes Investigator with a Juris Doctor and a master’s degree in history. I spent 10 years working in the New York State Division of Criminal Justice as Senior Analyst and Investigator. Today, I teach Cybersecurity, Ethical Hacking, Digital Forensics, and Financial Crime Prevention and Investigation. I conduct research in all of these, and run a non-profit that uses mobile applications and other technologies to create Early Alert Systems for natural disasters for people living in remote or poor areas.

Find more about me on Instagram, Facebook, Twitter, LinkedIn, or Mastodon. Or visit my non-profit’s page here.

To read about three aviation incidents in Nepal, click below. Thanks for reading!

Aviation Incident over Kathmandu

On April 24, 2023, some residents of Kathmandu were met by a spectacle in the sky—a Boeing 737-800 apparently on fire. Scheduled as a direct flight from Kathmandu to Dubai, Fly Dubai flight FZ576 experienced an engine problem upon takeoff from Tribhuvan International Airport (TIA). It eventually landed safely in Dubai at

Analyzing Yeti Airlines Flight 691

The preliminary report regarding Yeti Airlines Flight 691, which crashed in Pokhara, Nepal on January 15, 2023, has finally been released by the Aircraft Accident Investigation Commission of Nepal’s Ministry of Culture, Tourism and Civil Aviation. Occurring on a clear, sunny day, the flight crashed just between the runway of the old regional airport and…

The Tara Air Flight 197 Final Report

I previously wrote on this incident based on the release of the preliminary report. Nepal’s Civil Aviation Authority (CAAN) has now released its final report on the incident. This article will reference my previous, but with new detail and recommendations based on the latest findings.